+ Commands output when the jet power is changed + Commands output when the jet is turned offįinally for setting the power itself then for GRBL we just output the power: + Commands output when the jet is turned onįor turning the Laser off GRBL makes use of the gcode M5 command: We can now make use of our POWER variable, defined above as, to provide the required power value. For turning the laser on, GRBL makes use of gcode M4 command (normally intended for spindle direction, but 're-used' by GRBL for laser support ). In our GRBL example we haved added the 3 new block types. JET_TOOL_OFF - Output whenever the toolpath needs the laser off.JET_TOOL_POWER - Output whenever the toolpath needs the laser power to change.JET_TOOL_ON - Output whenever the toolpath needs the laser on.To allow Laser control, there are new Post Processor Blocks available in the Post Processor. The power value should be formatted as a whole number with no decimal points (1.0) and should be multiplied from its default by a factor of 10. We will replace the variable locations in our our toolpath output with the command 'S' (S). But we should only only output a command as the POWER value changes (C). To break this entry down in plain English, we are saying that the POWER output from our toolpath should be used everywhere in our subsequent post definition file where we have the the variable. The variable entry in the Post Processor reads: Although it can be set within the controller, the default setting for the maximum expected 'S' value - or laser power - is 1000.įor GRBL, therefore, we need to format the POWER variable to be a gcode 'S' command and scale its output value by a factor of ten so that it is in the range of 1 to 1000 (instead of the default 1-100). In laser mode, the controller will respond to a spindle speed control change by adjusting the power of the laser instead. Exampleįor GRBL-based controllers, the power setting for a laser is typically aliased to the gcode spindle speed control command 'S'. This is also the opportunity to scale the raw percentage value to the numerical range that your controller requires.

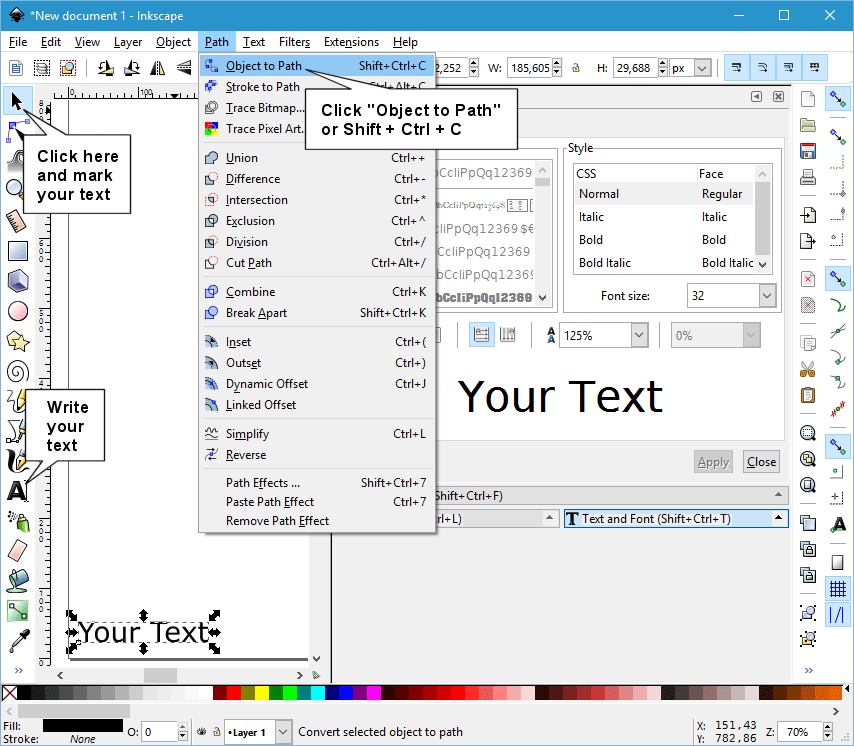

INKSCAPE GCODE TOOLPATH HOW TO

We need to add a new variable to show how to format this setting for your particular controller.

INKSCAPE GCODE TOOLPATH SOFTWARE

Vectric's software will output the power setting for a laser toolpath in the range of 1-100%. These examples are from the grbl (mm & inch) post processor provided by default with Vectric's software. The following sections deal with each area in turn and an example using the GRBL gcode controller is provided.

Add support for a new Power variable, which will be used by the new laser strategies.There are generally 4 areas that need to be modified in a conventional Post Processor to extend it for Laser toolpath support. Post Processors created without explicit support for the additional features documented here will not work correctly. These used workarounds to allow some router toolpath strategies, such as profiling, to be used with a laser head. Please note that many conversion kit manufacturers provided Vectric Post Processors before the release of the Laser Module. Previous Post Processors will not work correctly with the Laser Module

0 kommentar(er)

0 kommentar(er)